- Home

- Solutions

- Business Optimization

- Anchor Design Center

- Beyond Bond Comparison

ADVERSE CONDITIONS CAN’T STOP HILTI ADHESIVE ANCHOR SYSTEMS

Hilti adhesive anchor systems do what others cannot because they’re specifically designed to overcome factors that are often overlooked such as:

- The temperature of concrete or base material at the time of installation and curing

- The necessary preparations for successful hole drilling

- The moisture levels of concrete at the time of installation

Don't Let Tough Jobsites Set You Back

Hilti’s dedication to using technology to make construction faster, safer and more efficient shines through in the design of our high-performance adhesive anchors.

Downtime and delays often cost more than you can afford, but the performance of our chemical anchors help customers save on more than just the price of the product itself.

Hilti helps lower overall spend through:

- Lower usage costs

- Reduced installation costs

- Increased speed of production

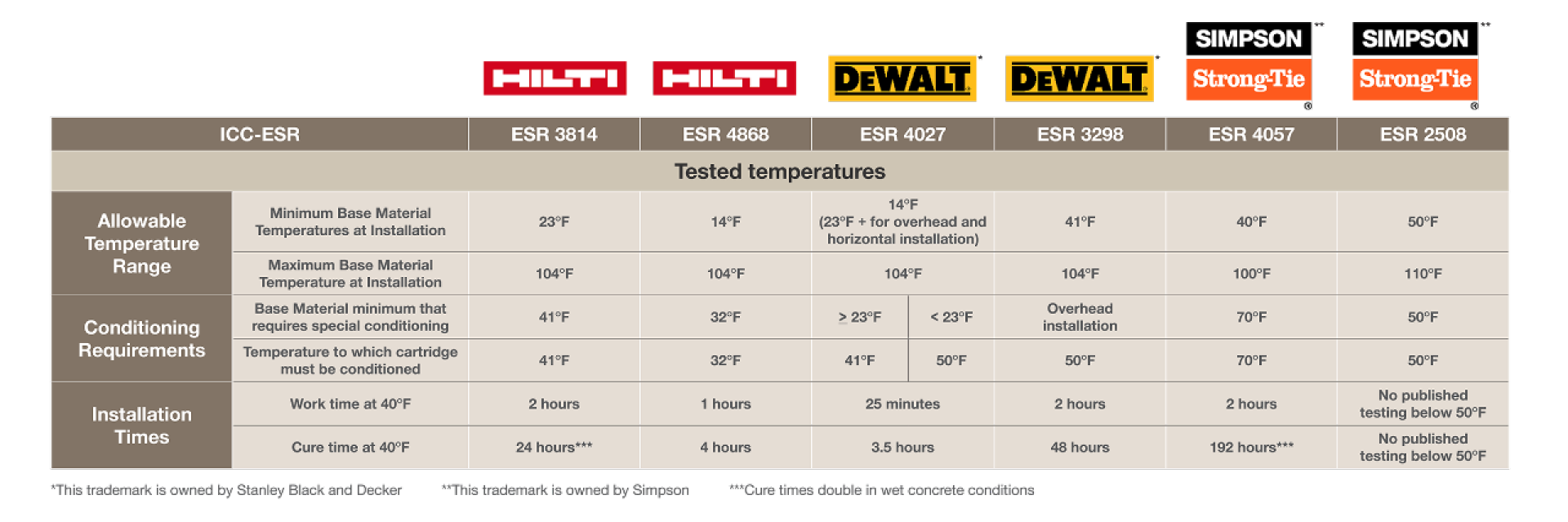

Temperature

A chemical reaction between the hardener and the resin is what allows two-part anchors to cure, but how fast or slow this process happens is completely dependent on the temperature of the base material where the anchor is installed. It’s important to know adhesive anchor systems can have various limitations, such as:

- The range of base material temperatures at the time of installation

- The time required for the adhesive anchor to cure

- The time permitted to install an adhesive anchor

- Conditioning requirements of the adhesive cartridge

Hole Drilling and Cleaning Methods

If a hole isn’t cleaned before installing an anchor, it won’t properly adhere and will inevitably cause headaches later on. Hilti created SafeSet to simplify the process using two different methods:

- A hollow-drill bit and vacuum system that removes dust and debris during the drilling process

- A proprietary anchor element, such as a Hilti HIT-Z rod, which requires no hole cleaning prior to install (highest load values in the industry)

Since OSHA’s increased silica dust regulations in 2016, many companies have developed similar technologies, but similar doesn’t mean equal. While other products might be able to remove dust and debris during installation, other aspects of the design fail where Hilti succeeds.

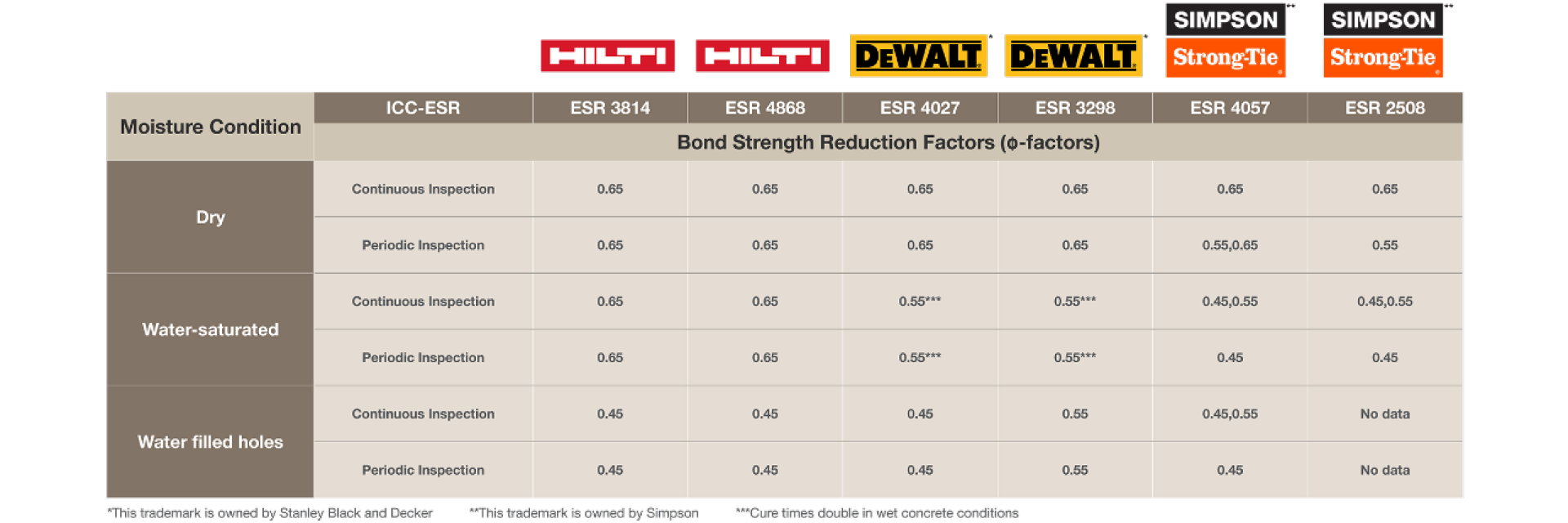

Moisture Condition of Base Material

Adhesive anchor systems are often more sensitive to adverse conditions. Unlike the competition, HIT-HY 200-A V3 (faster cure times for colder climates) and HIT-HY 200-R V3 (slower cure times for warmer climates) perform more reliably on jobsites that would have other adhesives creating downtime that no one wants to deal with.

Whether your design assumes dry or water-saturated concrete or water-filled holes, HY 200-A V3 and HY 200-R V3 chemical anchors present designers and contractors with an approved solution in both hot and cold climates.

![ACI 318-19: BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE 17.5.3 page 246 CODE Table 17.5.3(a)—Anchor strength governed by steel; Type of steel element; Strength reduction factor ⏀; Tension (steel); Shear (steel); Ductile 0.75 0.65; Brittle 0.65 0.60; Table 17.5.3(b)—Anchor strength governed by concrete breakout, bond, and side-face blowout; Supplementary reinforcement; Type of anchor installation; Anchor Category[1] from ACI 355.2 or ACI 355.4; Strength reduction factor ⏀; Tension (concrete breakout, bond, or side-face blowout); Shear (concrete breakout); Supplementary reinforcement present; Cast-in anchors; Not applicable 0.75; Post-installed anchors; 1 0.75; 2 0.65; 3 0.55; Supplementary reinforcement not present; 1 0.65; 2 0.55; 3 0.45; [1]Anchor Category 1 indicates low sensitivity to installation and high reliability; Anchor Category 2 indicates medium sensitivity and medium reliability; Anchor Category 3 indicates high sensitivity and lower reliability. Table 17.5.3(c)—Anchor strength governed by concrete pullout, or pryout strength; Type of anchor installation; Anchor Category[1] from ACI 355.2 or ACI 355.4; Strength reduction factor ⏀; Tension (concrete pullout); Shear (concrete pryout); Cast-in anchors; Not applicable 0.70; Post-installed anchors; 1 0.65; 2 0.55; 3 0.45; COMMENTARY The ⏀-factors for anchor strength governed by breakout, bond, and side-face blowout in Table 17.5.3(b) are separated into two groups based on the presence or absence of supplementary reinforcement. The supplementary reinforcement classifications f this table replace the “Condition A” and “Condition B” designations in previous Codes. Applications with supplementary reinforcement provide more deformation capacity, permitting the ⏀-factors to be increased. An explicit design of supplementary reinforcement for anchor-related forces is not required; however, the arrangement of supplementary reinforcement should generally conform to that of the anchor reinforcement shown in Fig. R17.5.2.1(a) and R17.5.2.1(b)(i) and (ii). Unlike anchor reinforcement, full development of supplementary reinforcement beyond the assumed breakout failure plane is not required. For concrete breakout in shear for all anchor types and for brittle concrete failure modes for cast-in anchors, the basic strength reduction factor for brittle concrete failures (⏀ = 0.70) was chosen based on results of probabilistic studies. While this factor is greater than the strength reduction factor of structural plain concrete (⏀ = 0.60), the nominal resistance expressions used in this chapter and in the test requirements are based on the 5 percent fractiles; therefore, ⏀ = 0.60 would be overly conservative. Comparison with other design procedures and probabilistic studies (Farrow and Klingner 1995) indicated that the choice of ⏀ = 0.70 is justified. For the same cases with supplementary reinforcement, the value of ⏀ = 0.75 is compatible with the level of safety for shear failures in concrete beams, and has been recommended in the PCI Design Handbook (MNL 120) and by ACI 349. Tests included in ACI 355.2 and ACI 355.4 to assess sensitivity to installation procedures determine the Anchor Categories as given in Table 17.5.3(b) for proprietary post-installed expansion, screw, undercut, and adhesive anchors. ACI 355.2 tests for installation sensitivity measure effects of variability in anchor torque during installation, tolerance on drilled hole size, and energy level used in setting anchors; for expansion, screw, and undercut anchors intended for use in cracked concrete, increased crack widths are considered. ACI 355.4 tests for installation sensitivity assess the influence of adhesive mixing and the influence of hole cleaning in dry, saturated, and water-filled/underwater bore holes.](/content/hilti/W1/US/en/business/business/engineering/anchors/beyond-bond-comparison/_jcr_content/childSections/childsection_1615381911/three_image_text_col_146167849/image_text_column/image.coreimg.jpeg/1643215671194/s7-aci-318-19-reduction-factor--base-material-sensitivity-.jpeg)

![ACI 318-19: BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE 17.5.3 page 246 CODE Table 17.5.3(a)—Anchor strength governed by steel; Type of steel element; Strength reduction factor ⏀; Tension (steel); Shear (steel); Ductile 0.75 0.65; Brittle 0.65 0.60; Table 17.5.3(b)—Anchor strength governed by concrete breakout, bond, and side-face blowout; Supplementary reinforcement; Type of anchor installation; Anchor Category[1] from ACI 355.2 or ACI 355.4; Strength reduction factor ⏀; Tension (concrete breakout, bond, or side-face blowout); Shear (concrete breakout); Supplementary reinforcement present; Cast-in anchors; Not applicable 0.75; Post-installed anchors; 1 0.75; 2 0.65; 3 0.55; Supplementary reinforcement not present; 1 0.65; 2 0.55; 3 0.45; [1]Anchor Category 1 indicates low sensitivity to installation and high reliability; Anchor Category 2 indicates medium sensitivity and medium reliability; Anchor Category 3 indicates high sensitivity and lower reliability. Table 17.5.3(c)—Anchor strength governed by concrete pullout, or pryout strength; Type of anchor installation; Anchor Category[1] from ACI 355.2 or ACI 355.4; Strength reduction factor ⏀; Tension (concrete pullout); Shear (concrete pryout); Cast-in anchors; Not applicable 0.70; Post-installed anchors; 1 0.65; 2 0.55; 3 0.45; COMMENTARY The ⏀-factors for anchor strength governed by breakout, bond, and side-face blowout in Table 17.5.3(b) are separated into two groups based on the presence or absence of supplementary reinforcement. The supplementary reinforcement classifications f this table replace the “Condition A” and “Condition B” designations in previous Codes. Applications with supplementary reinforcement provide more deformation capacity, permitting the ⏀-factors to be increased. An explicit design of supplementary reinforcement for anchor-related forces is not required; however, the arrangement of supplementary reinforcement should generally conform to that of the anchor reinforcement shown in Fig. R17.5.2.1(a) and R17.5.2.1(b)(i) and (ii). Unlike anchor reinforcement, full development of supplementary reinforcement beyond the assumed breakout failure plane is not required. For concrete breakout in shear for all anchor types and for brittle concrete failure modes for cast-in anchors, the basic strength reduction factor for brittle concrete failures (⏀ = 0.70) was chosen based on results of probabilistic studies. While this factor is greater than the strength reduction factor of structural plain concrete (⏀ = 0.60), the nominal resistance expressions used in this chapter and in the test requirements are based on the 5 percent fractiles; therefore, ⏀ = 0.60 would be overly conservative. Comparison with other design procedures and probabilistic studies (Farrow and Klingner 1995) indicated that the choice of ⏀ = 0.70 is justified. For the same cases with supplementary reinforcement, the value of ⏀ = 0.75 is compatible with the level of safety for shear failures in concrete beams, and has been recommended in the PCI Design Handbook (MNL 120) and by ACI 349. Tests included in ACI 355.2 and ACI 355.4 to assess sensitivity to installation procedures determine the Anchor Categories as given in Table 17.5.3(b) for proprietary post-installed expansion, screw, undercut, and adhesive anchors. ACI 355.2 tests for installation sensitivity measure effects of variability in anchor torque during installation, tolerance on drilled hole size, and energy level used in setting anchors; for expansion, screw, and undercut anchors intended for use in cracked concrete, increased crack widths are considered. ACI 355.4 tests for installation sensitivity assess the influence of adhesive mixing and the influence of hole cleaning in dry, saturated, and water-filled/underwater bore holes.](/content/hilti/W1/US/en/business/business/engineering/anchors/beyond-bond-comparison/_jcr_content/childSections/childsection_1615381911/three_image_text_col_146167849/image_text_column_1/image.coreimg.jpeg/1643215671467/s7-aci-318-19-reduction-factor--base-material-sensitivity-.jpeg)