- Home

- Solutions

- Business Optimization

- Earthquake Design Solutions

Earthquake Design Solutions

Insight into Hilti seismic research—with the potential impact for your applications

In seismic zones, routine construction challenges take on added importance. Hilti has invested in research and product development to help you achieve the earthquake design solutions and approvals you need.

In addition, we’ve developed multiple anchor and firestop systems for seismic applications. And our extensive education and engineering resources put greater insight and knowledge at your fingertips.

The Physics of an Earthquake

An earthquake generates additional loads on the structure in all directions as well as on piping, ductwork or cable trays.

Building codes (such as IBC, ASCE 7, CBC) provide simplified methods to calculate the seismic loads based on an equivalent static analysis.

Typical supports are designed for vertical loads but do not take into account horizontal loads.

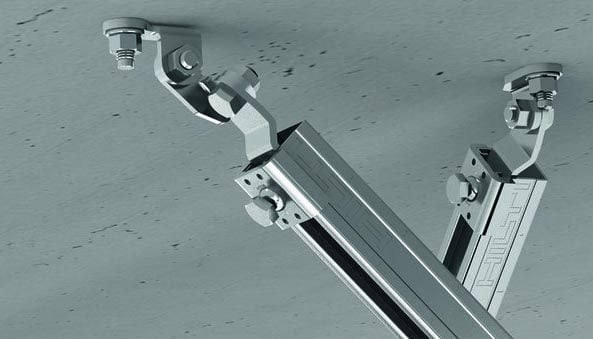

Seismic restraints allow systems to resist horizontal forces caused by earthquakes. Bracing in longitudinal and transversal directions keeps systems in place and secure.

Post-Installed Anchor Seismic Design

When you are designing or building in medium- to high-seismic zones—Design Categories C through F—you need more than just promises; you need proof. Our educational and documentation resources provide anchor system seismic performance and acceptance criteria across a variety of test standards and industry approval resources.

Metal Deck Fastening Seismic Design

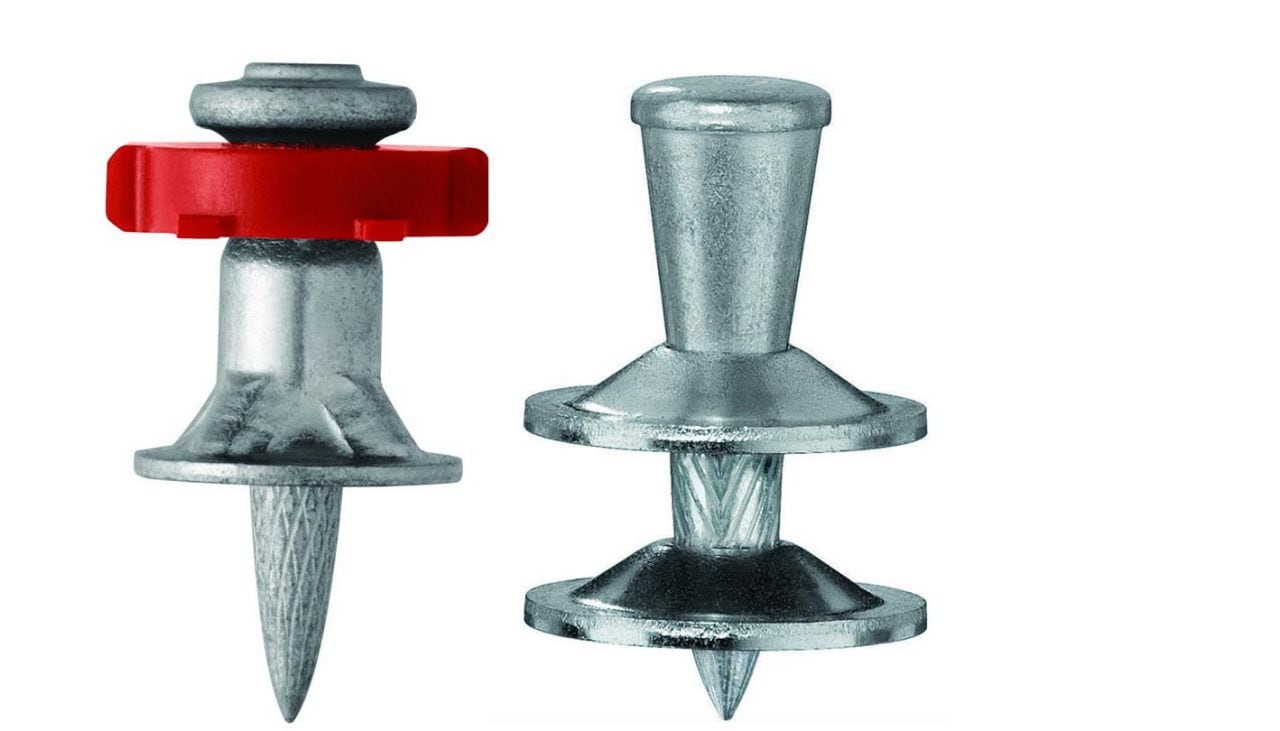

Ductility and the ability to dissipate energy under cyclical seismic loading conditions are key concerns about steel deck diaphragm integrity in an earthquake. Hilti mechanical fastening systems for attaching steel decking to bar joists and structural steel have shown superior performance in both areas, as compared to spot welds. (See the accompanying videos.)

In fact, Hilti X-HSN 24 frame fasteners designed for fastening steel deck to bar joists and X-ENP-19 frame fasteners for fastening decking to thicker structural beams are both qualified for design in seismic zones, with ICC-ES, FM, and UL approvals and COLA certificates. They provide installation efficiencies in terms of speed and consistent quality as well.

Hilti Earthquake research and testing

A proactive approach to seismic performance

At Hilti we believe strongly in research and development, running our own labs and testing facilities and working with partners all over the world.

For seismic testing, we worked with our partners at the Department of Structural Engineering at the University of California, San Diego. In a five-story building at the Network of Earthquake Engineering Simulation (NEES) shake table facility, Hilti engineers measure integrated building systems in lifelike simulations of earthquake forces.

Using sensors and video cameras, we analyze the effects of seismic activity on anchor and firestop performance. So when you choose Hilti products in seismic applications, you can trust them to meet or exceed not only the appropriate regulations—but also your expectations. It’s an exciting project where we’ve been conducting full-scale performance tests on our products using the largest vibrating table in the world – a specially constructed five-story building subjected to a series of shocks at 1:1 on the Richter scale.

It’s been a great opportunity to research and design our seismic products. This includes all system which reduce installation time and provide quality performance.

-

Hilti participates in a landmark seismic and fire research project at UCSD NEES facility

-

UCSD Shake Project

Building Non-structural components earthquake testing

-

Building Nonstructural Component Systems Earthquake Test

-

Fixed foundation tests

If the building where you are working is an older structure that does not include base isolators to reduce the impact of a seismic event, learn more about the role anchors and firestop systems can play in enhancing safety in similar environments.

Post-earthquake fire performance

There’s a big difference between evaluating firestop performance in a laboratory versus testing it in an actual building subjected to simulated earthquake forces. Because our earthquake research includes building firestop systems subjected to lifelike simulation of 7.9 and 8.0 magnitudes, you can see how to maximize your firestop system protections for post-earthquake challenges.