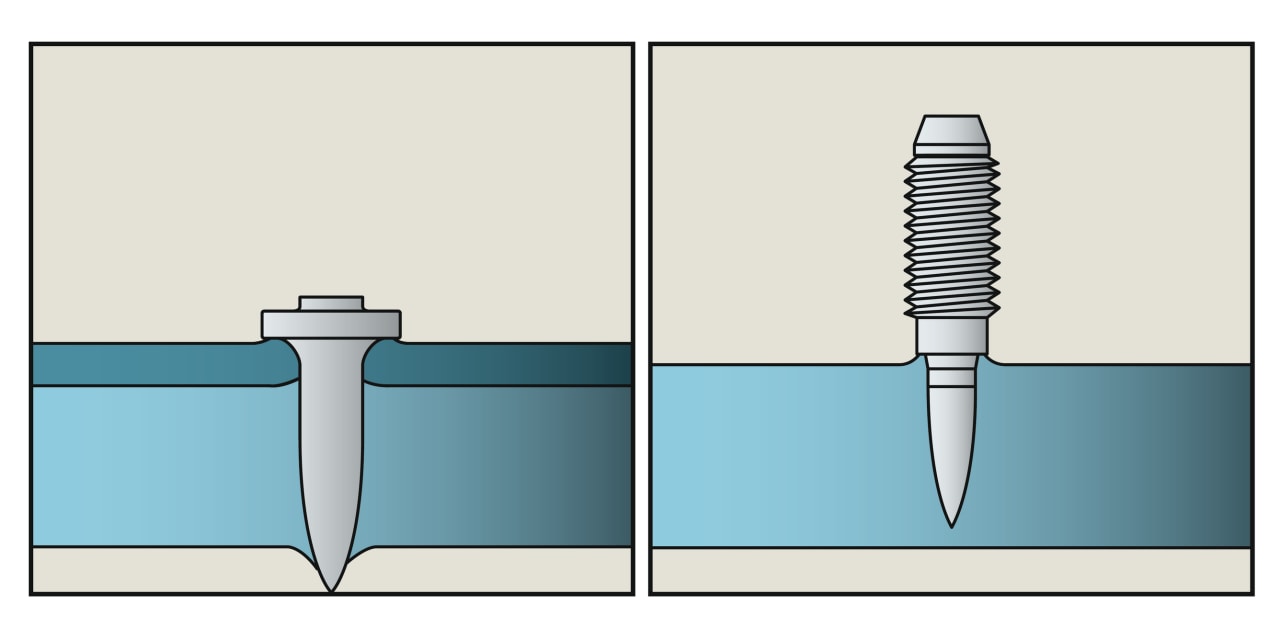

Sharp tip fastening

A cost-competitive, one-step solution for high-frequency fastening where speed is critical.

How it works:

With X-R or X-ST sharp tip fasteners, a sharp tip stainless steel fastener is driven by a battery powered or powder-actuated tool into the base material, creating a higher-quality connection.

Benefits:

- Faster one-step installation

- Fastens a wide variety of materials

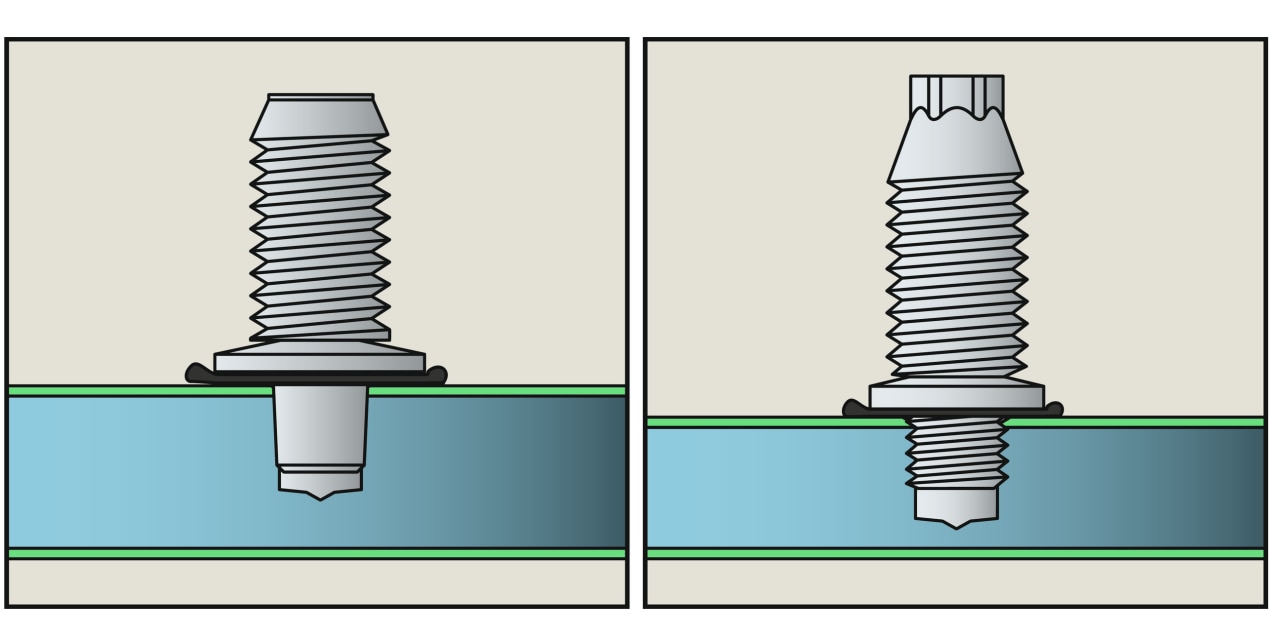

Blunt tip fastening

Versatile 2-step solutions for daily fastening to steel across a broad range of applications.

How it works:

With X-BT or S-BT blunt tip fasteners, a threaded fastener is driven or screwed into a pre-drilled hole in the base material by a powder or battery-powered tool.

Benefits:

- No damage to corrosion protection in non-through penetration applications

- Fastening in as little as 2 minutes

- Stainless steel fasteners – equivalent corrosion protection as A4 (316) for highly-corrosive environments

- Duplex coated carbon steel fastener for mildly-corrosive environments

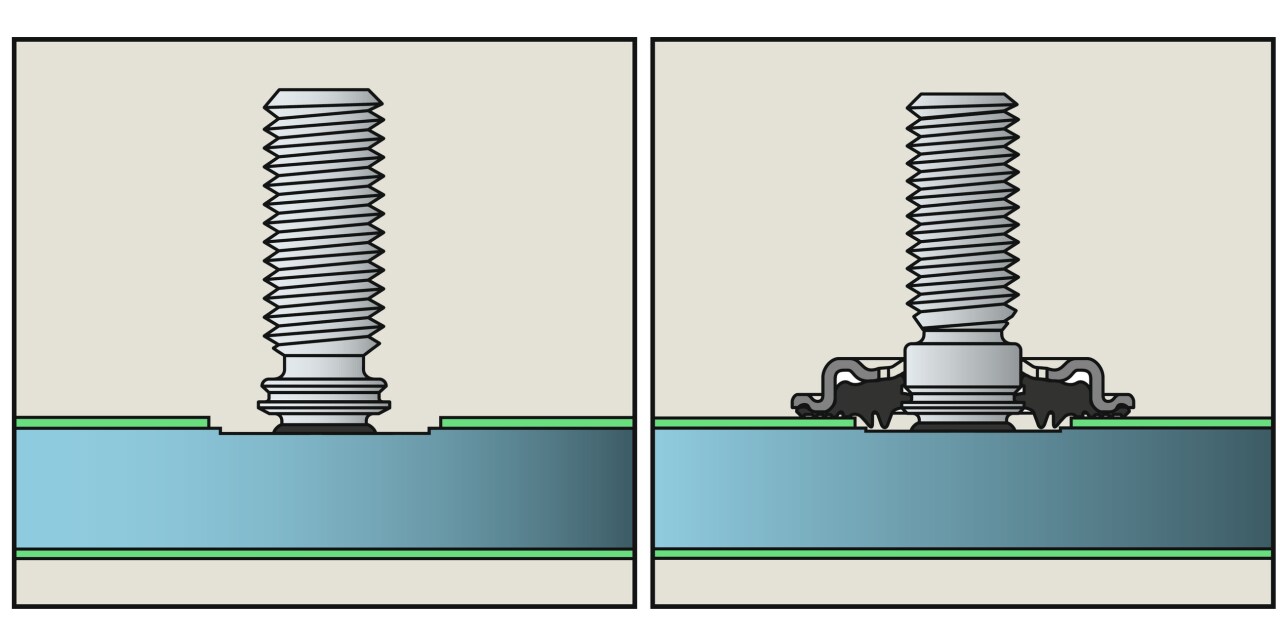

Fusion welding

For higher-strength fastening to steel in demanding, engineered applications – combines welding performance with more ease of use.

How it works:

With F-BT stud fusion, a threaded metal stud is welded by a battery-powered tool on a prepared surface. The optional washer then seals the prepared surface for a fastening point with long-term corrosion resistance.

Benefits:

- No damage or burn-through to rear side of corrosion protection coating and simple front side sealing helping to virtually eliminate rework

- No drilling or notching into base material required, helping maintain base material integrity

- Higher-load, thin base and versatile fastening point

Share