- Home

- Solutions

- Business Optimization

- Anchor Design Center

- What's In Your Bond Strength?

What's In Your Bond Strength?

Understand how factors influence performance of adhesive anchors

Model codes like the International Building Code (IBC) and American Association of State Highway Transportation Officials (AASHTO) reference ACI 318 for post-installed anchoring provisions listed in Chapter 17. This design methodology is commonly referred to as “Strength Design,” and replaced the older methodology of Allowable Stress Design, or ASD. Per ACI 314, adhesive anchors must comply with ACI 355.4, which are the qualifications for testing of post-installed adhesive anchors. Using these criteria as a reference, manufacturers will test their adhesive anchor systems through third-party evaluation services such as the International Code Council Evaluation Service (ICC-ES) or International Association of Plumbing and Mechanical Officials (IAPMO). Evaluations of performance should be approved by the Authority Having Jurisdiction (AHJ).

The resulting evaluation report is important to validating the anchoring system you select, design, and install as a fastening point is appropriate for the application… and has been tested to perform in realistic conditions for that application.

We design products that help mitigate the adverse conditions that impact performance of adhesive anchors

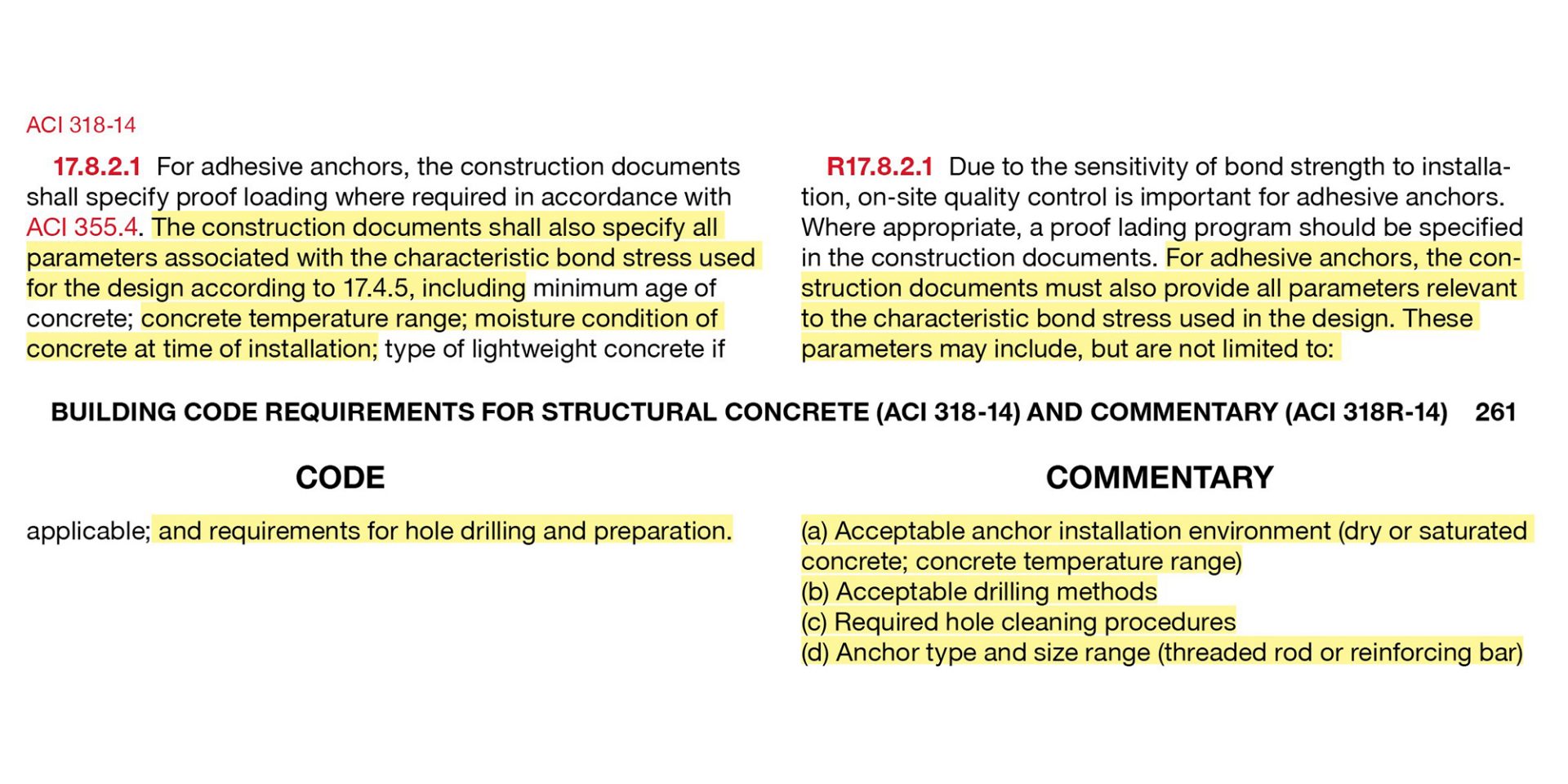

ACI 318 17.8.2.1 requires that parameters associated with bond stress be specified

- Concrete temperature range

- Moisture condition of concrete at time of installation

- Acceptable hole drilling methods and required hole cleaning procedures