- Home

- Solutions

- Business Optimization

- Decking Design Center

Decking Design Center

Simpler, smarter alternatives to welding

Hilti mechanical fasteners for metal decking offer significant advantages—including rain-or-shine installation, simple visual inspection and a reliable connection that meets or exceeds codes code requirements.

Efficiently attach metal decking to open web steel joists or structural steel without the complications of conventional methods. Using the industry-leading Hilti powder-actuated fastening system, you can install a variety of steel deck profiles in a fraction of the time.

Why Choose Mechanical Deck Fasteners?

Mechanical deck fasteners are more consistent and cost-efficient compared to conventional methods, such as puddle welding

Puddle welds vs Deck fasteners

The human element

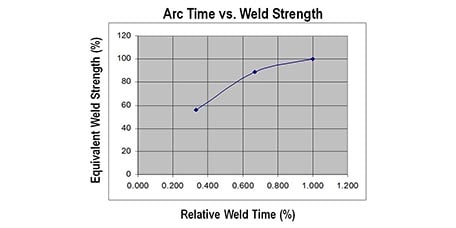

Research conducted by Virginia Tech colleagues Gregory L. Snow and W. Samuel Easterling found that arc time has a tremendous effect on weld strength (as represented in the graph above). Proper arc welding for steel deck spot welding takes an average of 8.1 seconds for a 5/8" puddle weld and 12.8 seconds for a 3/4" puddle weld. A lack of consistency in human performance for puddle welding in the field can result in significant reductions in weld strength.

Weld inspections

In reference to a typical weld inspection, an official in Vancouver said: “[I] check the puddle size. Not really anything else you can do.”

But because weld diameter is confirmed by a visual inspection, welders may increase the amperage on their equipment to achieve a bigger puddle—without ensuring proper fusion. Mechanical fasteners do not allow for this kind of manipulation.

Mechanical deck fasteners

When asked about Hilti mechanical deck fasteners, the same inspector said: “[I] check to see that the pins were installed into the steel below. Pins are better because they are verifiable.”